Henkel has developed and commercialized a novel series of die attach materials to facilitate package-level sintering, addressing the regulatory challenges of high-lead solders, thermal conductivity drawbacks of conventional die attach pastes, and processability shortcomings of traditional sintering products. The patent-pending LOCTITE® ABLESTIK® ABP 8068T portfolio includes high thermal, semi-sintering die attach pastes that offer simplified processing, and best-in-class thermal and electrical performance with robust reliability for today’s high power density devices.

The expanded functionality and shrinking dimensions of devices within mobile, datacom/telecom, consumer and automotive applications are driving increased power densities and resulting in the need to manage heat dissipation more effectively. The use of thermal interface materials provides this relief at the board and component level, but more capable solutions at the die level are an important piece of the holistic thermal management equation.

“Historically, solder has been the predominant solution for high thermal and electrical performance,” explains Raj Peddi, Henkel Market Segment Head for Wirebond IC Packaging, “but its impending phase out due to environmental legislation is driving the need for alternative materials. Other approaches such as conventional high thermal die attach adhesives and pure silver sintering products are also less than ideal because of interfacial contact limitations and processability challenges. For these reasons, Henkel developed the LOCTITE ABLESTIK ABP 8068T series of semi-sintering die attach materials which combine high thermal conductivity, robust reliability and simplified manufacturing processes.”

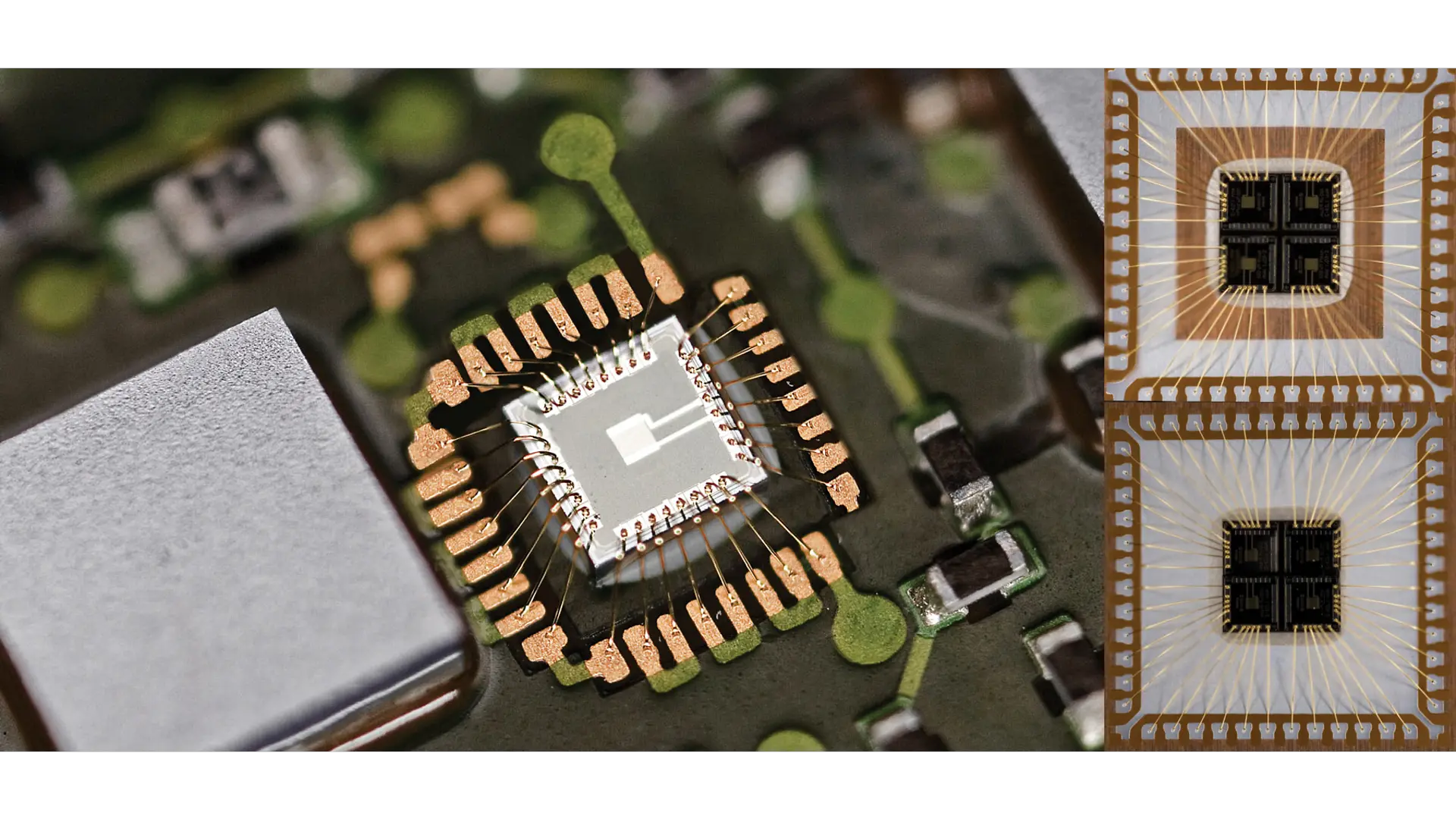

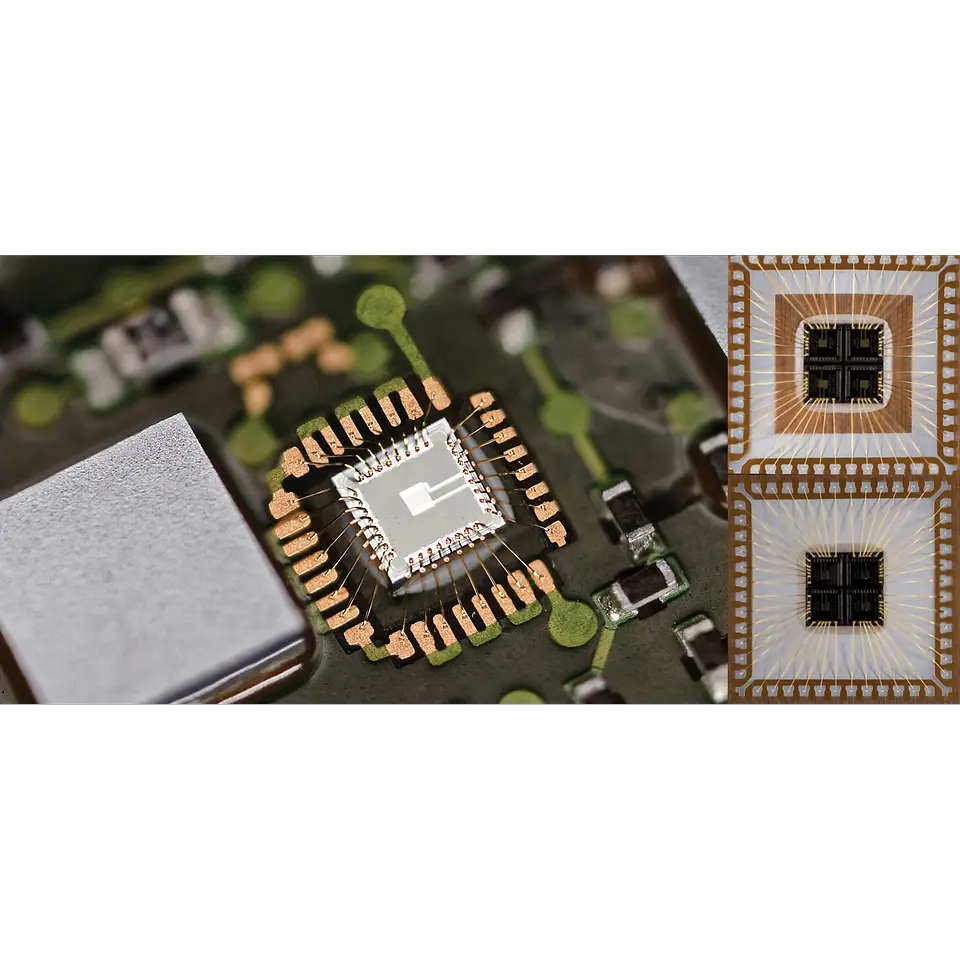

Henkel’s new high thermal, semi-sintering die attach adhesives provide a lead-free alternative for die attach within high power density semiconductor packages. LOCTITE ABLESTIK ABP 8068T series materials can be implemented using standard processes without the need for high pressure and temperature, as is the case with conventional silver sintering materials. Because the novel die attach pastes form an interpenetrating network of sintered silver (Ag) and resin, they establish excellent contact with the interface for void-free bond lines to achieve outstanding thermal conductivity and result in good thermal cycling performance. LOCTITE ABLESTIK ABP 8068T series materials are a drop-in replacement solution for standard die attach applications, can be cured with nitrogen or air, and have robust adhesion on a variety of surface finishes including silver, copper, nickel-palladium-gold and gold.

Other attributes of LOCTITE ABLESTIK ABP 8068T series materials include applicability on a wide range of die sizes up to 5 mm x 5 mm; excellent thermal performance with bulk thermal conductivity up to 110 W/m-K and low in-package resistance of about 0.5 K/W for silver, copper and nickel-palladium-gold lead frames; and broad workability that includes consistent dispensing up to 24 continuous hours, open time of two hours and stage time of as long as four hours.

“Truly, for high power density semiconductor packages, this is the solution manufacturers have been seeking,” says Peddi, noting the material’s combination of performance, reliability and processability. “For packaging specialists that want a lead-free replacement for solder that doesn’t require expensive or complicated processing, yet ensures equal or better performance as compared to conventional materials, the LOCTITE ABLESTIK ABP 8068T portfolio delivers.”

For more information, visit henkel-adhesives.com/electronics and/or register to attend a free August 22nd webinar to learn more about market trends and how the semi-sintering material is addressing new requirements.