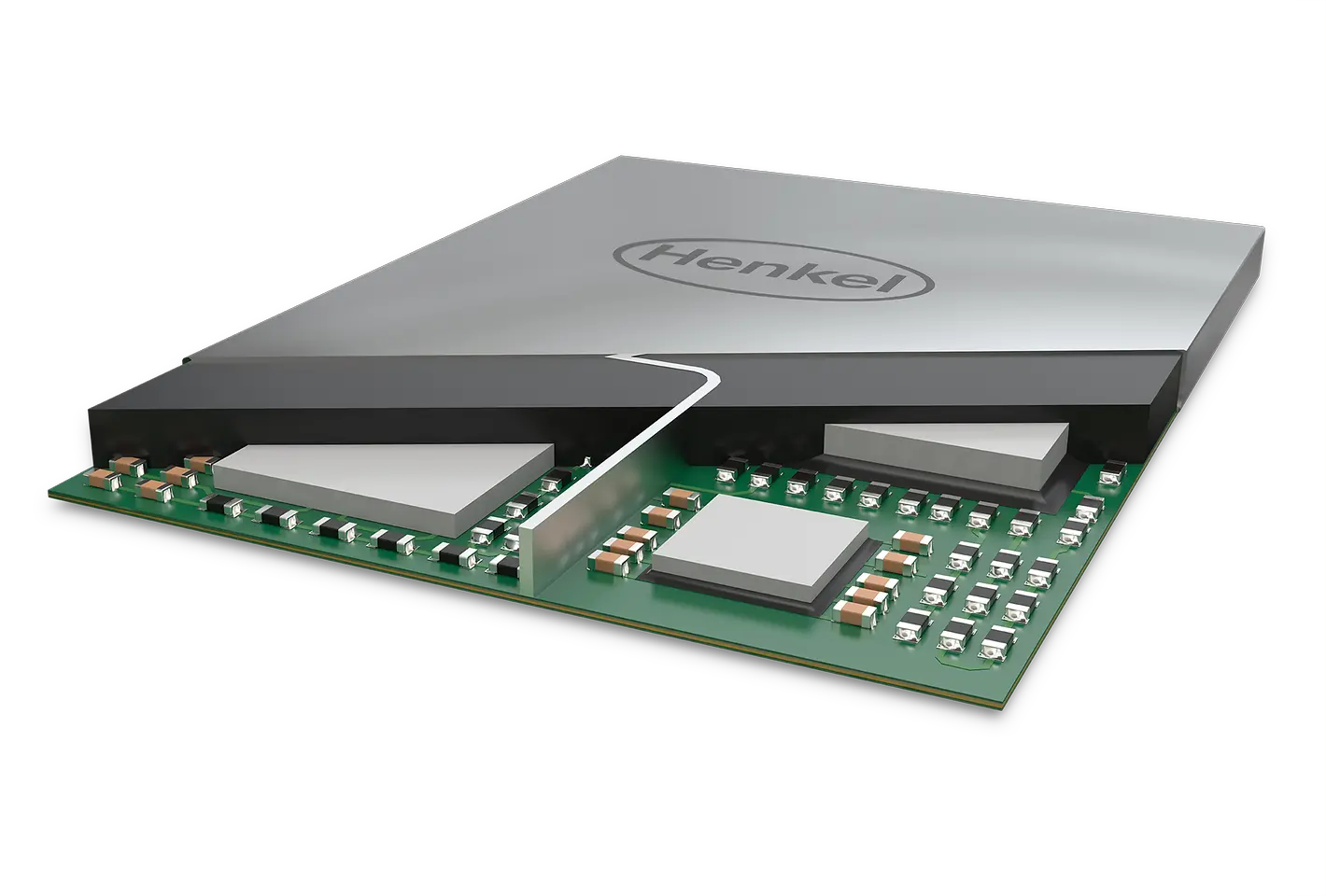

The drive to develop electronic materials capable of handling the reliability and performance demands of emerging integrated packages for 5G wireless communication and ADAS automotive systems has resulted in next-generation formulations that leapfrog conventional products. Henkel is at the forefront of this development and, from booth 516 at the Electronic Components and Technology Conference (ECTC), Henkel advanced packaging experts will showcase novel electronic materials designed for various device configurations including fan-in and fan-out wafer-level packages (WLPs), 2.5 and 3D thru-silicon via (TSV) architectures, flip chips and SiPs.

Among the featured Henkel 5G and ADAS device solutions are:

Conference attendees interested in learning more about EMI shielding solutions for thinner, high-frequency packages should attend Henkel’s presentation on the subject, scheduled as part of the ‘Advanced Materials for High Speed Electronics’ session. Xuan Hong, Henkel Scientific Principal, will present her “Highly Conductive Compartment EMI Shielding Material with Jet-dispensing Technology” paper on May 30th at 11:15 a.m. To register, visit ectc.net/registration.

Continuing to lead the market in advanced packaging materials development, Henkel is enabling the future of mobile communication and automotive safety and control. Meet the technical team at ECTC booth 516 to discuss specific applications and learn more about Henkel solutions, or visit henkel-adhesives.com/electronics.