To manage the greater data bandwidth needs inherent with 4k rich media streaming, machine learning, data mining, and analytics, next-generation hyper-scale and cloud-scale datacenters are transitioning to the 400 gigabit ethernet (GbE) standard. While higher-speed switching and routing is necessary to manage 5G network traffic volumes, ensuring optimal performance through effective heat management is challenging, and conventional thermal interface materials (TIMs) for pluggable optical modules (POMs) are not ideal.

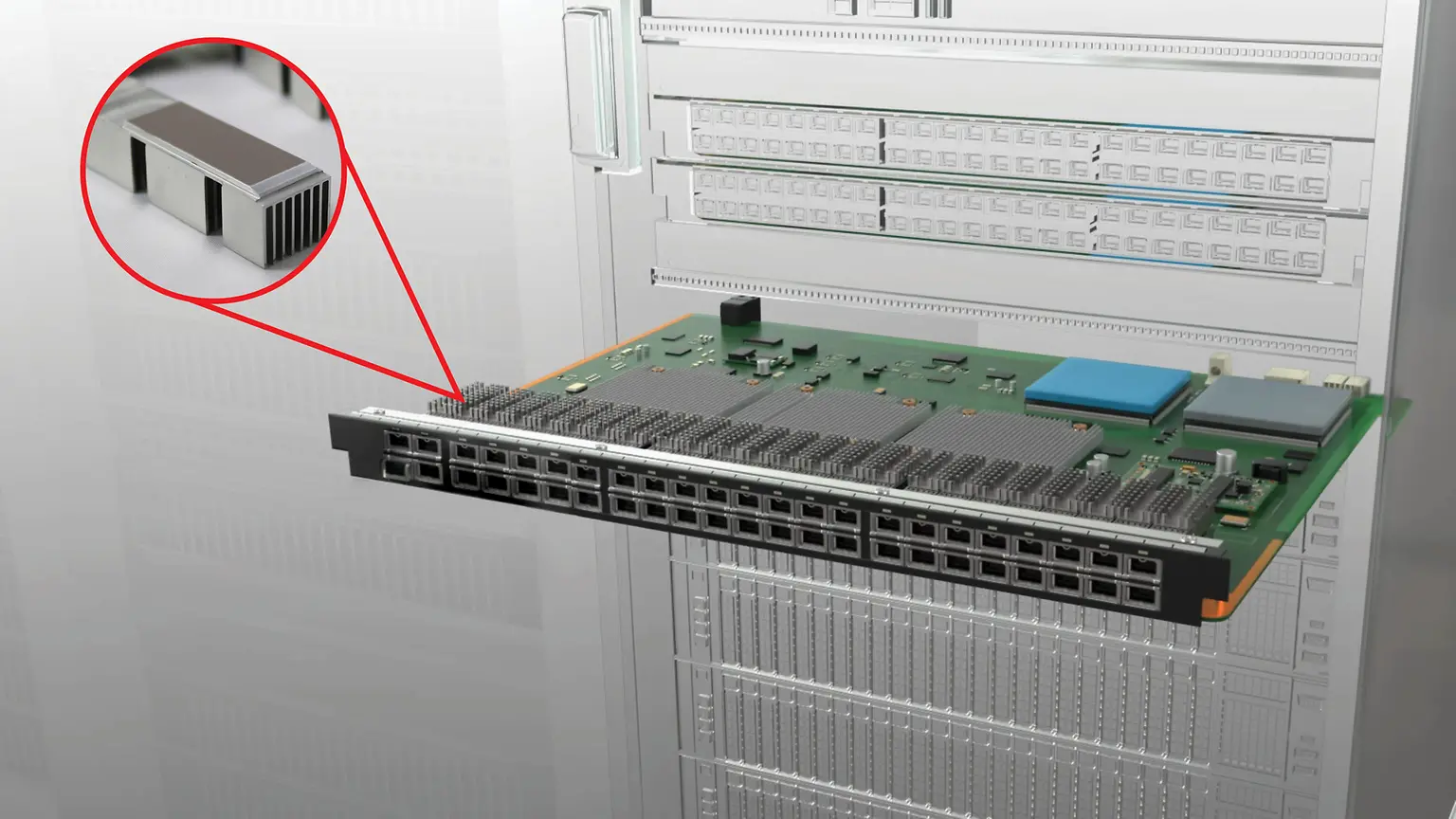

Henkel has developed new micro-thermal interface coatings, the BERGQUIST microTIM mTIM 1000 series, that offer a robust heat-dissipating solution and are conducive to the operational realities of state-of-the-art datacenters. Applied to networking line card heatsinks that come in contact with POMs, BERGQUIST microTIM mTIM 1000 series are durable, thermally conductive thin film coatings designed to enhance thermal performance between the module and the heatsink. With the transition to 400 Gb modules, the power level per POM – which number as many as 32 per line card – can reach as high as 15 watts. BERGQUIST® microTIM mTIM 1000 series materials facilitate greater heat dissipation from the module, reducing operational temperature at a rate of 0.33° C per watt. For a 15-watt module, temperature reduction is upwards of 5° C, which is significant in aggregate across the line card.

“Part of the heat dissipating effectiveness is due to the materials’ durability and application adaptability,” explains Wayne Eng, Henkel Global Head of Market Strategy, Telecom and Datacom, “Unlike conventional TIM pads or tape workarounds, which often get scraped off as the modules are removed and re-inserted, our new microTIMs easily withstand repeated insertions and pulls. Together, the thermal performance and durability help address our customers’ high power 400 GbE performance and deployment challenges.”

Applied to the heatsink in an ultra-thin 20 µm layer, BERGQUIST® microTIM mTIM 1000 series materials are silicone thermoset resins that provide excellent durability, allowing repeated pulls and plugs and good thermal transfer to a riding heatsink. In customer testing, more than 500 module insertions and removals – which far exceeds the industry test standard – did not diminish the materials’ performance. Henkel’s microTIMs are resistant to salt corrosion, abrasion and vibration, and are compatible with service temperatures from -40° C to +200° C.

Details about the novel POM thermal solutions will be shared at this year’s Optical Fiber Communication (OFC) Conference and Exhibition, taking place March 10-12 at the San Diego Convention Center. Those interested in learning more about the materials and their in-application performance should register to attend the below joint paper on March 12 at 2:00 p.m. in Room 7:

For more information about Henkel’s new microTIMs or any of the company’s thermal and adhesive solutions for telecom and datacom applications, visit henkel-adhesives.com, call +1-855-243-6535 or send an e-mail to electronics@henkel.com.