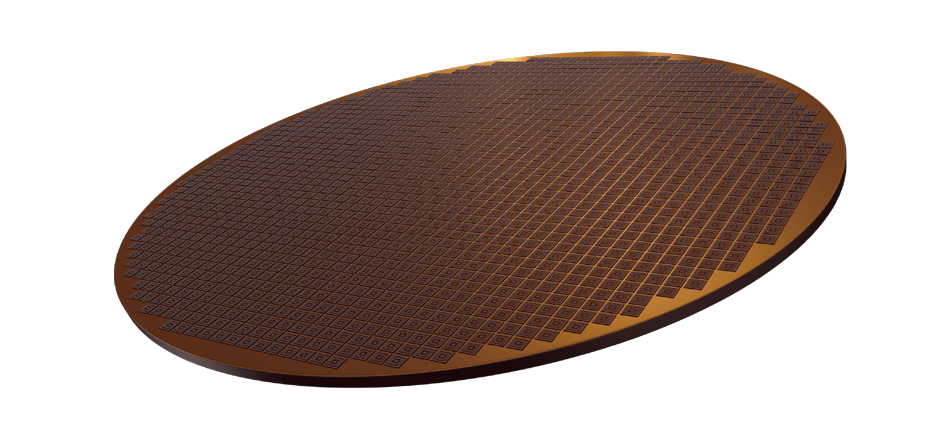

Henkel Corporation today announced the commercial availability of LOCTITE ECCOBOND LCM 1000AF, a breakthrough encapsulation material that leverages a unique anhydride-free resin platform to enable thorough protection, improved warpage control and fine gap filling for fan-in and fan-out wafer-level packages (FI WLPs, FO WLPs). LOCTITE ECCOBOND LCM 1000AF, which is REACH-compliant, has shown effective reliability-enhancing performance in internal evaluations of several wafer-level packaging configurations including FI WLPs, embedded wafer-level ball grid arrays (eWLBs), FO WLPs, and chip-on-wafer (CoW) encapsulation.

As chip integration and new packaging technologies gain steam to address the cost, form factor and functional realities of accelerated electronics miniaturization, FO WLP and FI WLP approaches are increasingly being adopted, particularly for applications such as data processors, mobile devices, consumer electronics, and radio-frequency communication chipsets. However, with thinner dies – some as thin as 50 µm or less –conventional anhydride-based molding materials may not meet today’s challenging requirements.

Henkel’s Global Market Segment Head for Semiconductor Packaging Materials, Ramachandran (“Ram”) Trichur, explains that traditional liquid compression molding materials are built on anhydride resin systems with larger filler sizes, which can limit warpage control effectiveness in FO WLP processes and the ability to penetrate narrow gaps for trench filling with FI WLP techniques. “The powder-type fillers often used in older-generation standard wafer encapsulation systems have large particle sizes that range from 25 µm to an upper cut of 50 µm,” he says, noting that some of the trenches between dies in FI WLP processes are as thin as 40 µm wide. “Standard encapsulants are challenged to thoroughly fill high-density structures and, during fan-out wafer-level processing, have also shown warpage of greater than 2.0 mm after molding, both factors that can impact long-term reliability and wafer handling. Henkel’s anhydride-free epoxy liquid compression molding material resolves these issues.”

LOCTITE ECCOBOND LCM 1000AF is a solvent-free encapsulant that integrates exceptionally fine particle fillers (average 3 µm, upper cut 10 µm), enabling high-yield, ultra-low warpage, excellent flow properties for void-free fine-dimension filling, and fast in-mold cure times for improved UPH. In testing, LOCTITE ECCOBOND LCM 1000AF exhibited the following performance benefits:

“The ultra-low warpage, improved handling, high throughput processing, thorough five- or six-side protection and void-free performance of our new LCM serve to dramatically enhance reliability and long-term device durability,” Trichur says, underscoring the significance of the new material development. “However, we didn’t stop there. At the same time, LOCTITE ECCOBOND 1000AF delivers these attributes in an anhydride-free formulation that complies with strict REACH standards and in keeping with Henkel’s commitment to sustainability. Wafer-level packaging just took a huge leap forward.”

For more information about LOCTITE ECCOBOND 1000AF or to request a sample, visit Henkel’s semiconductor web resource, and complete the ‘contact us’ form.