Henkel and Ford to co-present at leading global bodywork event on pioneering aluminum for high volume vehicle manufacturing

Aluminum plays a vital role in today’s automotive manufacturing environment. As well as being half the weight of steel, its thermal and electrical conductivity increase recyclability and provide outstanding corrosion resistance, further optimizing internal combustion engine vehicles, and driving growth of the electric vehicle market. As a leader in adhesives, sealants, and functional coatings for the automotive industry, Henkel enables the broader use of aluminum to deliver greater performance, sustainability, and process efficiency.

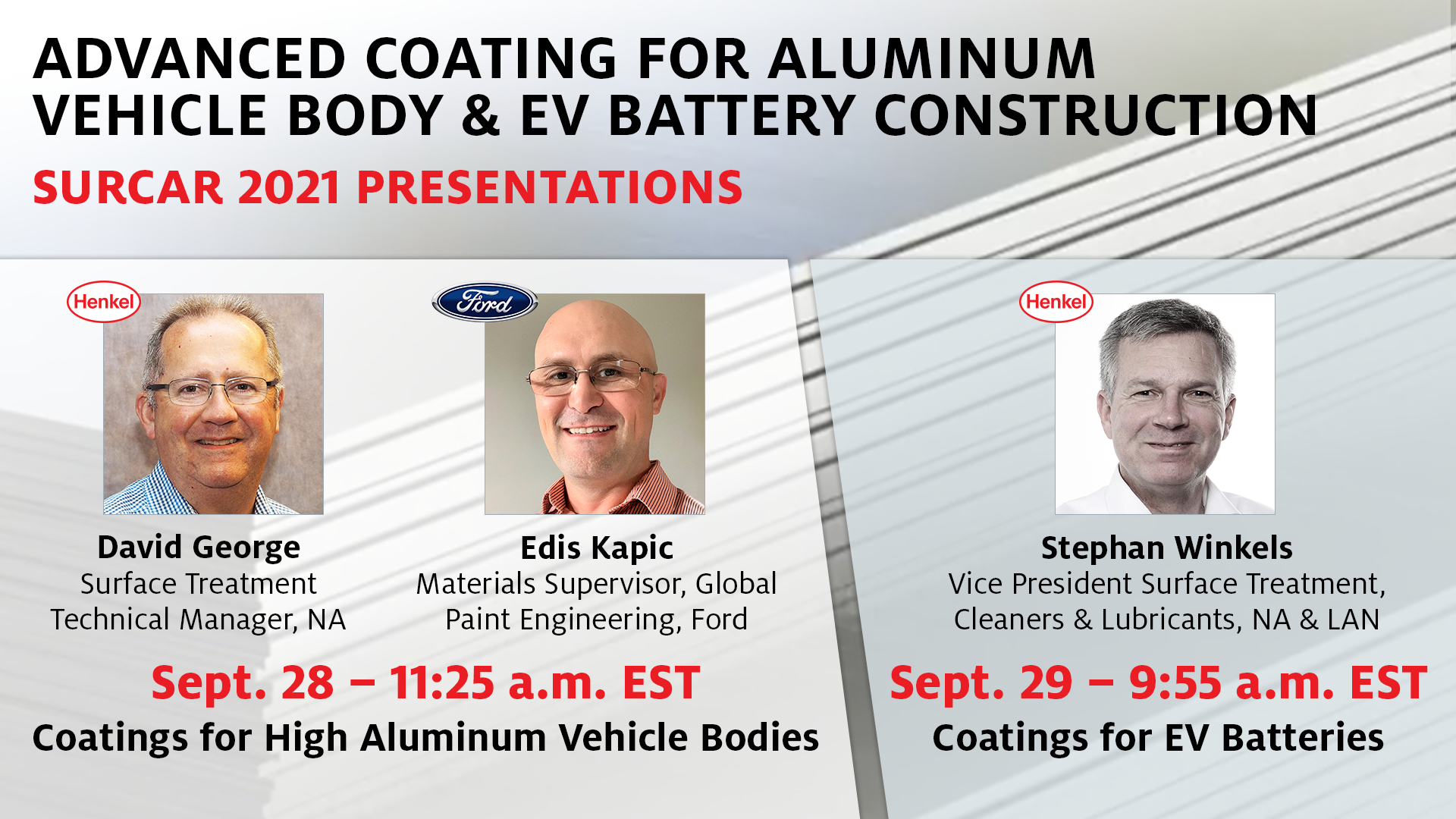

At SURCAR 2021, the leading global event for the world’s car body finishing industry, held from September 28-29, in Detroit, Michigan, Henkel will deliver two presentations on the breakthrough technologies that are helping optimize aluminum applications in bodywork and EV battery manufacturing.

Tuesday, Sept. 28 - Next Generation Metal Pretreatment for High Aluminum Vehicle Bodies

In conjunction with Ford Motor Company, Henkel will describe the successful metal pre-treatment techniques that the companies first pioneered together for application on the 2015 all-aluminum Ford F-150. Entitled “Practical Application & Robust Benefits of Next Generation Metal Pretreatment for High Aluminum Vehicle Bodies,” David George, Surface Treatment Technical Manager at Henkel and Edis Kapic, Paint Materials Development and Release Supervisor, Ford VOME Global Paint Engineering, will review the evolution of zirconium oxide-based chemistry in the metal pretreatment process. Formulated for enhanced corrosion protection and paint adhesion on vehicle bodies with up to 100 percent aluminum, Ford has successfully implemented the conversion coating chemistry as part of Henkel’s BONDERITE® Thin Film Process on several all-aluminum vehicle lines, including the Expedition, Navigator and F-150.

This joint presentation will also discuss the significant business and environmental advantages of the process. These include reduced upfront capital investment for greenfield sites, lower labor/maintenance and environmental advantages, and operational cost savings from the near elimination of sludge and reduction in energy and water usage. Moreover, the significantly improved corrosion performance allows for potential consumer benefits, such as extended cosmetic warranties.

Wednesday, Sept. 29 - How Coatings Enable State of the Art Battery Construction

In a presentation entitled “Coatings Enabling Automotive State of the Art Battery Construction”, Dr. Stephan Winkels, Vice President Surface Treatment, Cleaners & Lubricants at Henkel, will describe how coatings help to facilitate aluminum battery housing and cell construction to the highest safety standards.

The presentation will look at the multitude of coatings required in the manufacture of the modern car battery. For housing components, Winkels will describe how different coatings should ideally be developed to be compatible - for example to allow for easy removal to enable subsequent process steps – and in terms of the key performance attributes, factors such as charging performance, heat management and safety means that coatings, adhesives, and gap-fillers must offer high corrosion resistance, supreme thermal conductivity, and extremely low electrical conductivity.

As well as a providing a practical look at the various stages where coating, adhesive and gap filler solutions are implemented, Winkels will also offer insights into the optimal chemistries and processes applicable to ensure the performance, safety, and longevity of EV batteries.

To learn more about SURCAR 2021, view the full program and register to attend, please visit surcar-northamerica.com.