Low Pressure Molding, Thermal Management and Structural Adhesives Leadership on Display; Papers Highlight Reliability and Sustainability

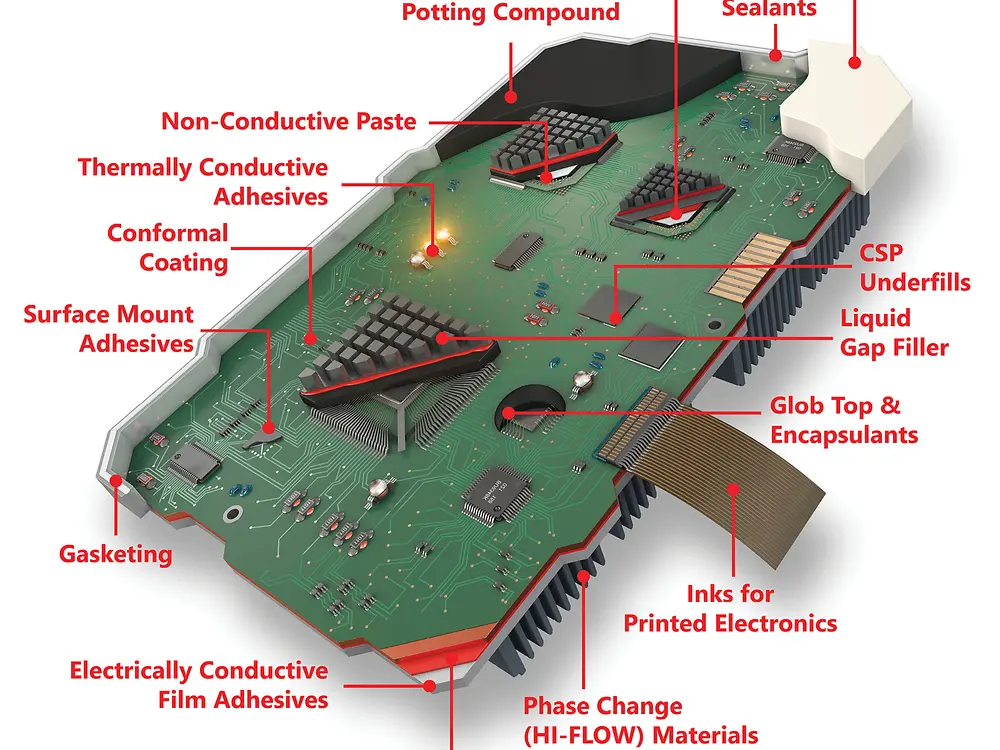

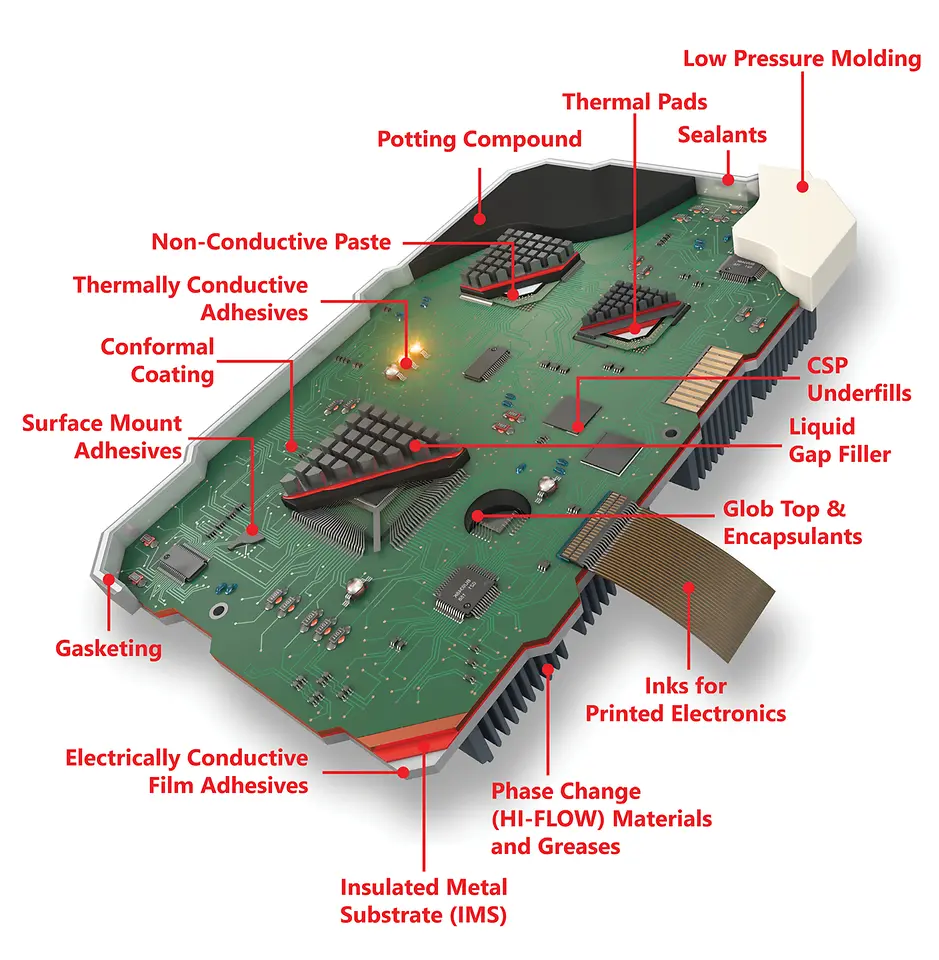

Prioritizing the requirement across market sectors for increased reliability and sustainability, Henkel’s exhibit and paper presentations at next week’s IPC APEX EXPO 2022 (APEX) will showcase the material leader’s commitment to these objectives. Live demonstrations, a range of protection, connection and thermal control solutions and the company’s pioneering work on sustainable adhesive development will be front and center. Henkel’s portfolio, displayed at APEX in Booth 1734, is designed to improve cost-efficiency, in-field reliability and longer lifetimes.

Groundbreaking Biobased Consumer Electronics Adhesive

Earlier this year, Henkel debuted the market’s first biobased polyurethane reactive (PUR) hot melt adhesive for consumer electronics assembly, LOCTITE® HHD 3544F. At APEX, Henkel Global Head of Sustainability for Electronics, Scott Anderson, will deliver a poster paper presentation on the product’s development, the formulation challenges and the resultant material, with over 60% of its content sourced from renewable, plant-based feedstocks. The adhesive is ideal for structural bonding applications within mobile phones, laptops, wearables and accessories.

Thermal Management for 5G Infrastructure and Industrial Devices

Low volatility BERGQUIST® brand liquid thermal gap fillers and thermal gels provide robust thermal control and high-volume manufacturing compatibility for numerous industrial applications. Showcasing its award-winning BERGQUIST LIQUI-FORM TLF 6000HG thermal gel, which has enjoyed broad success in 5G infrastructure applications, Henkel technologists will engage in live, in-booth dispensing demonstrations of the material to illustrate the one-part thermal gel’s application ease. With thermal conductivity of 6.0 W/m-K and 3.0 mm gap stability, the material is well-suited for devices such as baseband units, remote radios and antennas that are positioned vertically in outdoor environments.

Simple, Three-Step Low Pressure Molding

Electronic component protection from moisture, vibration and environmental contaminants is a key part of the reliability equation. Meeting these goals cost-effectively and efficiently can be challenging. Henkel’s TECHNOMELT low pressure molding materials reduce the complexity of the encapsulation process to three easy steps. Available in a variety of formulations and colors, TECHNOMELT hot melt adhesives are used for applications in the medical device, electronics, LED lighting and automotive markets, among others. The ability to re-melt unused material reduces waste and delivers a sustainable alternative to other protection materials.

Development and Application Expertise

Throughout the event, the Henkel team will participate in several panel discussions and conference papers. Learn from some of the industry’s most knowledgeable materials experts by attending the below:

Reliability and Thermal Control:

- “Ability of Industry Reliability Methods to Predict Lifecycle Application Field Failures”, Alex Sanchez, Henkel Senior Applications Engineer Americas, Jan. 25, 10:00 a.m. – 12:00 p.m.

- “Silicone Migration Concerns in Thermal Materials – How Real are They?”, Sanjay Misra, Ph.D., Henkel Senior Scientific Principal, Jan. 25, 1:30 – 3:00 p.m.

- “Thermally Conductive EMI Management Materials for High Frequency Applications”, Bongjoon Lee, Ph.D., Henkel Scientific Principal, Jan. 25, 3:30 – 5:00 p.m.

Sustainability:

- “Increasing Awareness and the Impending Impact of Sustainability Metrics in the Electronics Ecosystem”, Neil Poole, Ph.D., Henkel Chemistry Fellow, Jan. 26, 3:30 – 5:00 p.m.

- “Developing a Biobased Structural Adhesive for Consumer Electronics”, Scott Anderson, Henkel Global Head of Sustainability for Electronics, Jan. 25, 5:00 – 6:00 p.m.; Jan. 26, 2:30 – 3:30 p.m.; Jan. 27, 12:00 – 2:00 p.m. on the show floor.

For more information about Henkel’s materials for consumer electronics and industrial applications, visit henkel-adhesives.com. To schedule a technical consultation during APEX, send an email to: eva.laus@henkel.com.