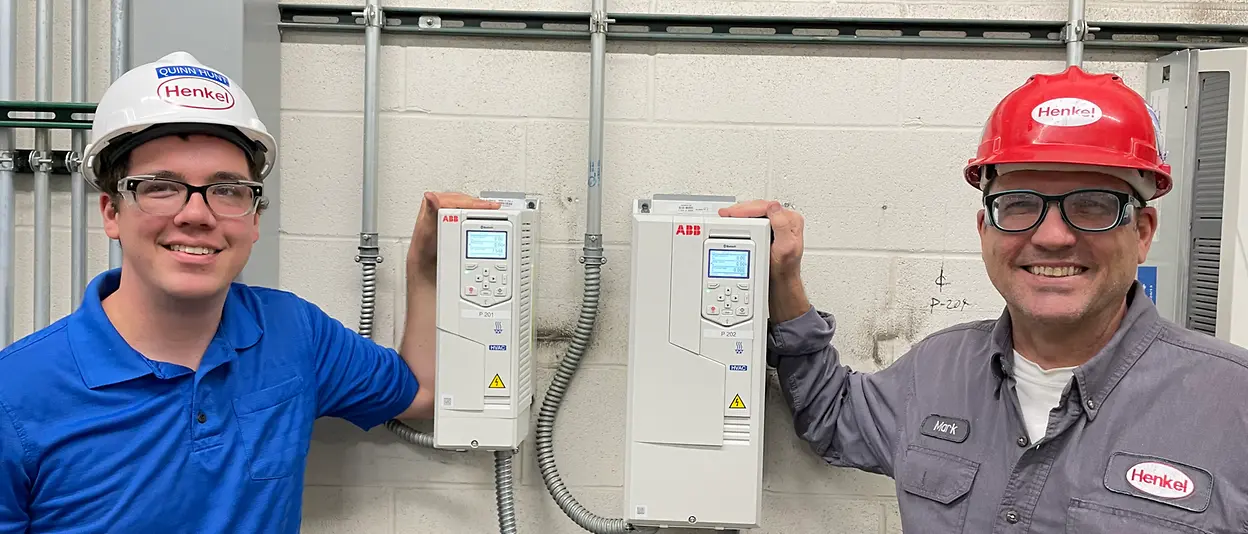

Constructed by Henkel, the Elgin, IL site located on Gasket Drive broke ground in the late 1980s and has been an essential contributor to the company’s success ever since. Today, nearly 100 employees from engineering, product development, quality management, logistics, and operations make this vibrant, five-day-a-week, three-shift site a powerhouse of production, technical expertise, and innovation. Both liquid and hot melt polyurethane adhesives are produced here at massive scale – totaling thousands of tons annually. The adhesives – sold under the LOCTITE®, LIOFOL®, TECHNOMELT®, and TYCEL® brands – are used to build flexible food packaging like drink and coffee bean pouches, provide structural stability to RVs, encapsulate electronics for protection, and enable engineered wood products used for mass timber building assemblies among others.