Henkel Corporation’s Adhesive Electronics (AE) business today announced the commercial availability of a new, high-strength adhesive designed for streamlined assembly of optical components and modules. The material, LOCTITE® STYCAST® OS 8300, is a two-part, dispensable epoxy adhesive conducive to high-volume manufacturing requirements and delivering improved adhesion performance* as compared to previous-generation materials.

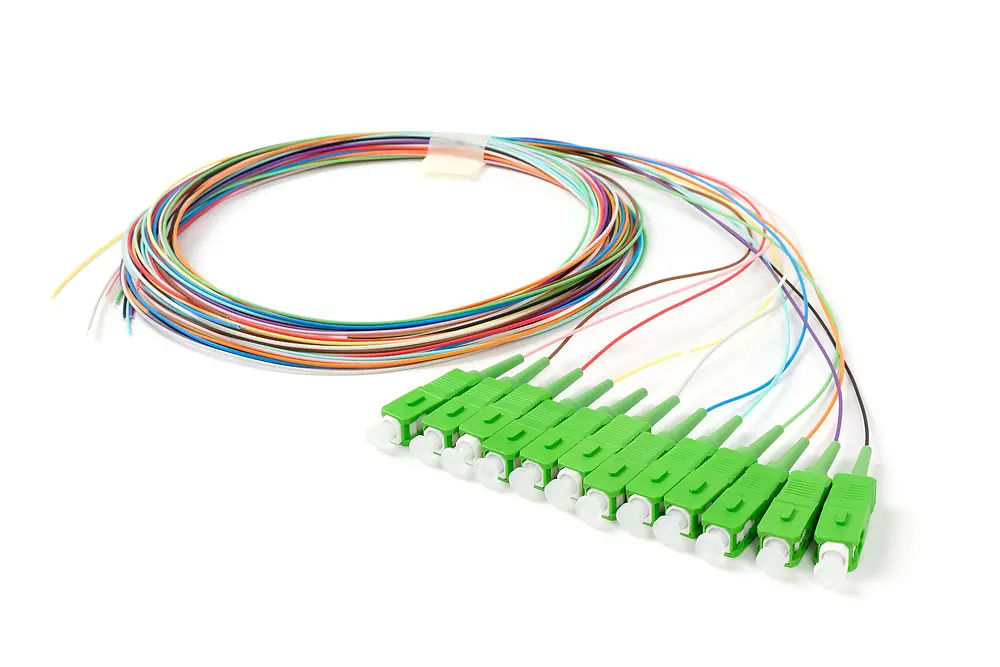

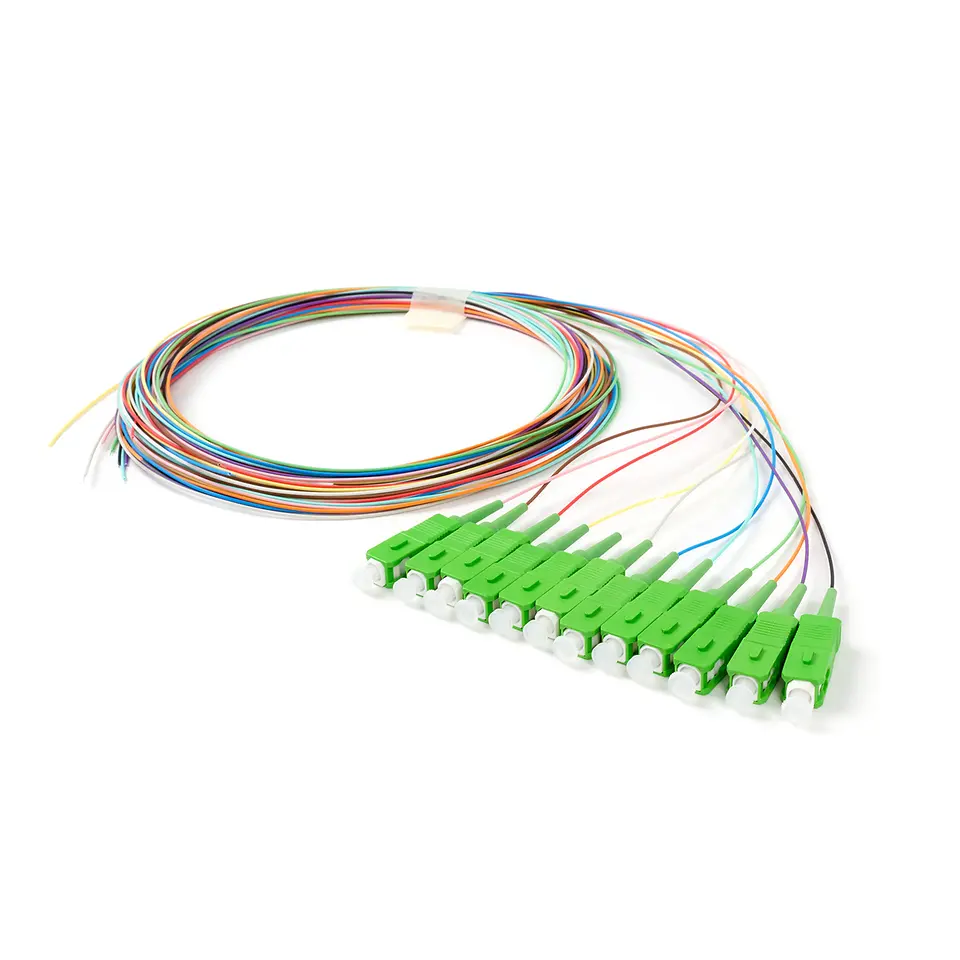

LOCTITE STYCAST OS 8300 is the latest addition to Henkel’s broad portfolio of two-part epoxies for bonding of fiber and glass in optical fiber applications. Its adhesion bond strength on multiple substrates including glass and FR4 laminate is 18 kg*, which is a significant improvement over alternative materials and provides highly reliable and robust in-use performance. In addition to a strong bond, LOCTITE STYCAST OS 8300 is formulated with a matched refractive index for optimal light transmission, has low weight loss for reduced risk of optical component contamination, and an improved work life to enable extended processing time. All of these advantages make the material ideal for FAU, ROADM and optical cable assemblies.

“The growth of telecom and datacom applications and requirements for faster data transfer speeds are extraordinary,” notes Farida Jensen, Henkel Americas Business Development Manager, Telecom/Datacom. “The integrity and performance of critical optical devices depend on the alignment accuracy and long-term adhesive stability of the bonded components, and Henkel’s latest material delivers.”

To meet the demand for telecom and datacom components, high-throughput production is essential. With fast dispensing speeds and quick curing capability, LOCTITE STYCAST OS 8300 facilitates the challenging pace of high-volume optical component assembly. Quick cure at relatively low temperature (80°C) and the ability to store material at room temperature before mixing also allow optoelectronics manufacturers to reduce energy cost and support sustainability objectives.

“Henkel continues to build on its already-broad optical products portfolio, with LOCTITE STYCAST OS 8300 addressing emerging processing and reliability requirements of passive and active optical component assembly,” Jensen says in summary, noting the positive response the material received during its debut at the recent OFC conference. “Our engineering teams are completely focused on developing new products for optoelectronics applications that will meet the expectations for higher speeds, higher bandwidth, lower power consumption and smaller form factors of modern telecom and datacom systems.”

For more information, follow this link or call +1-888-943-6535.

*As per internal lab testing. Sample cured @150°C, die shear strength at 25°C on glass to glass, 2 x 2 mm die, Kg>15.