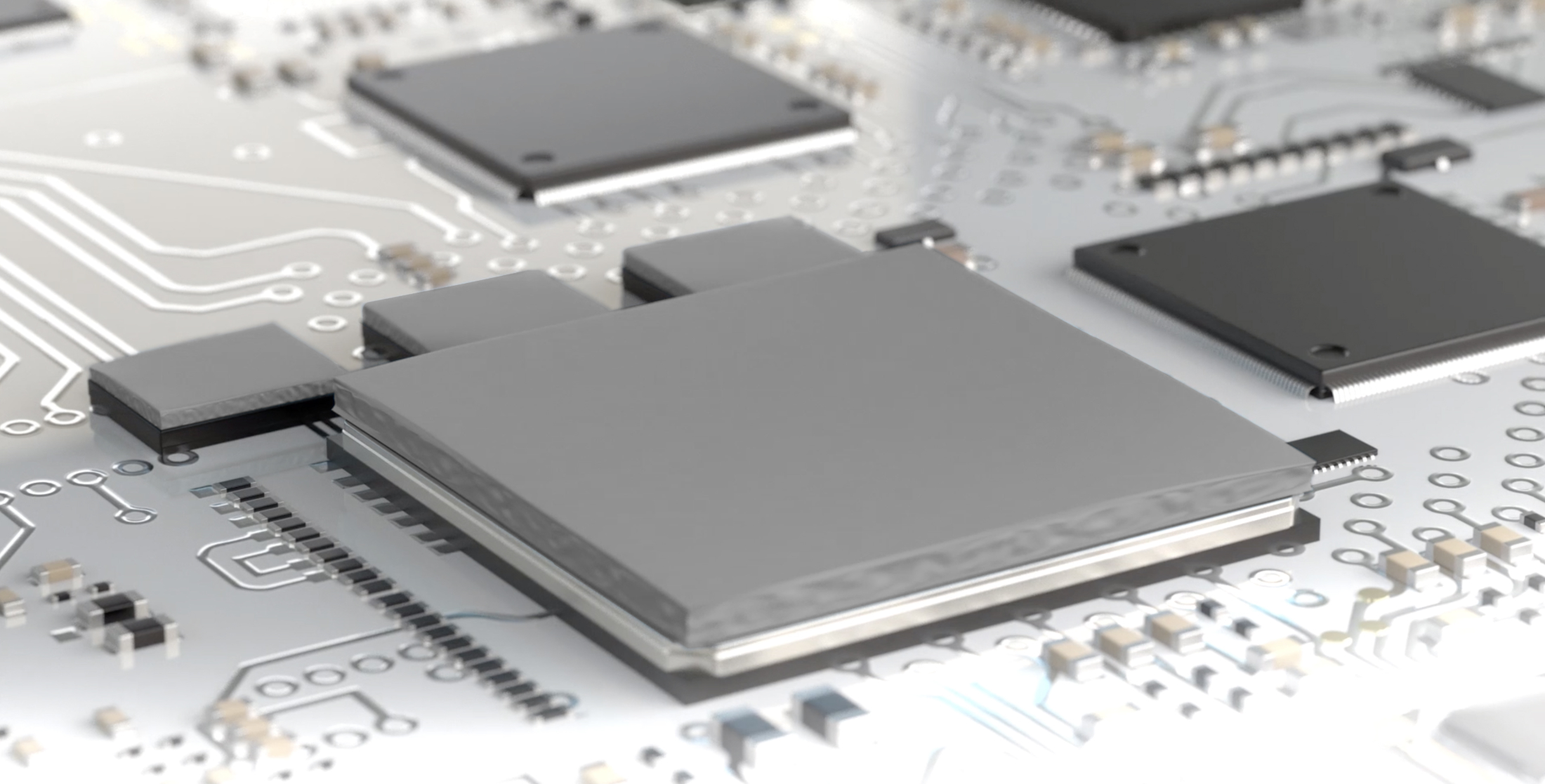

Henkel today announced the expansion of its award-winning thermal interface materials (TIMs) portfolio with the addition of a product developed to address the high power density challenges associated with new 5G telecom infrastructure and consumer mobility designs. BERGQUIST® GAP PAD® TGP 10000ULM is a formulation that provides exceptionally high thermal conductivity of 10.0 W/m-K within an ultra-low modulus, low assembly stress formulation. The combination of these characteristics makes the material one of the highest performing TIMs available in the market today, an innovation which earned the material a coveted Circuits Assembly NPI Award at last month’s IPC APEX EXPO event.

“Because more functional, miniaturized telecom infrastructure components are required for 5G connectivity, higher power densities will be the norm,” explains Wayne Eng, Henkel Global Head of Market Strategy, Telecom and Datacom. “High-end routers, servers, switches and base band units continue to pack more capability into already small footprints. High thermal conductivity solutions are a necessity to dissipate the resulting heat for assurance of system reliability and optimal performance.”

Well-known for their high compliance, surface conformability and low stress, BERGQUIST GAP PADs have long been employed for telecom and datacom applications to effectively minimize the adverse impact of heat on device operation and lifetime. Henkel, addressing current and future market requirements, developed the latest GAP PAD to manage the challenging thermal loads inherent with increased power densities.

BERGQUIST GAP PAD TGP 10000ULM and a soon-to-be-released 12.0 W/m-K product are soft, high compliance pads that conform to irregular surfaces, filling small gaps to enable interface wet out and optimal thermal transfer. The unique filler technology and low modulus formulations unite high thermal conductivity with low assembly stress, minimizing component damage while offering robust heat removal from critical components. With 10.0 W/m-K thermal conductivity capability, the new BERGQUIST GAP PAD offers telecom infrastructure designers the freedom to integrate high power devices with confidence.

“Customer qualification and notable industry recognition of our latest thermal interface materials development is further validation of Henkel’s innovation priorities,” says Eng in conclusion. “We are appreciative of the positive feedback and are grateful to the NPI Awards judging panel for recognizing the importance of Henkel’s TIM solutions to the advancement of 5G technology.”

For more information about Henkel’s BERGQUIST thermal interface material products, visit henkel-adhesives.com.