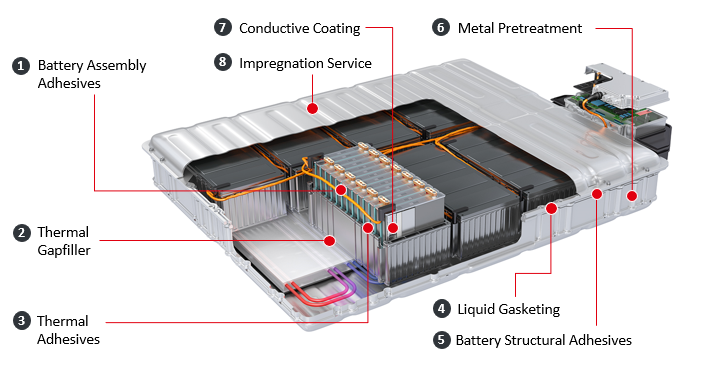

New silicone-free thermal management materials, high-strength adhesives and protective gasketing products among EV battery innovations on show

At the 2019 Electric & Hybrid Vehicle Technology Expo in Novi, MI, Henkel will display its latest material technologies for cost-effective high-volume assembly, protection and thermal control of next-generation electric vehicle (EV) battery systems. Show delegates are invited to attend several Henkel speaker events and visit the expert e-Mobility team in booth 1201 from September 10 – 12.

Understanding the competitive requirements to lower battery cost, raise performance and ensure operational safety and reliability, Henkel materials specialists have developed novel formulations that allow for large-scale production at high speed, reduce the risk of thermal event-related safety concerns, and enable various battery architectures including cylindrical, pouch and prismatic cell designs. Some of the company’s newest innovations being featured include:

Thermal management solutions:

As the leader in thermal interface material (TIM) development, Henkel understands that robust thermal management of battery cells and modules is essential for safety, operational reliability and extended lifetime performance of the battery pack. At the Electric & Hybrid Vehicle Technology Expo, the company debuts its latest automation-enabling innovation which eliminates the risk of silicone outgassing. The 3.0 W/m-K silicone-free liquid Gap Filler, BERGQUIST® TGF 3010APS, provides ample thermal performance while removing any concern of silicone interference in the auto body paint operation. Booth visitors can also learn more about the full portfolio of thermal materials including award-winning high compliance BERGQUIST® GAP PADS® and thermal adhesives with structural shear strength of >10 MPa to accommodate for varying coefficients of thermal expansion (CTEs).

Battery assembly adhesives:

As automotive manufactures look to increase production speed and flexibility, adhesive solutions that allow for the fast assembly of large quantities of cells are becoming increasingly important. Henkel’s line of TEROSON® and LOCTITE® battery assembly adhesives offer accelerated cure (< 15 sec.) and strong adhesion with multi-surface adaptability throughout the battery system – from cell to cell, cell to carrier and battery frame to tray. Among the newest solutions, TEROSON MS9396 is a silane-modified, one component moisture cure material with high adhesion to multiple substrates, delivering a solution for applications where good elongation is required.

Gasketing materials:

Battery pack housings are secured through the use of Henkel liquid gasketing technologies that provide protection from leakage and defend against external contaminants. Process and service friendly, the range of form-in-place and cure-in-place gasketing materials allow the top cover of the pack to be reopened for serviceability or repair. Additionally, the materials are flame retardant and UL94 compliant.

Robust underfill protection materials:

Designed specifically for challenging environments, LOCTITE ECCOBOND® UF 1173 underfill offers protection of array devices within high operating temperature, high reliability automotive applications. The one-component underfill can be jet or needle dispensed, flows fast in and around tight interspaces and cures quickly to form void-free interconnect protection from shock, drop and vibration. Additionally, the material has been formulated with health and safety top-of-mind; it contains no reportable REACH SVHCs* (substances of very high concern) and is not CMR classified.

LOCTITE high-reliability solders:

Battery management system control boards demand electrical interconnect integrity for proper function and reliability. Henkel’s award-winning LOCTITE GC temperature stable solder pastes and its high-reliability 90iSC alloy, which was designed in cooperation with automotive industry leaders, provide proven performance for today’s automotive electronic systems.

In addition to its exhibit presence, Henkel technical experts will share their specialist knowledge during conference presentations, Exhibit Theater educational sessions and in-booth demonstrations. Learn more by attending the following:

- Conference Presentation -- Next-generation Environmentally-Friendly Thermal Solutions for EV Batteries Henkel’s Director of Thermal Technology, Reid Chesterfield, September 11th from 4:00 to 5:00 p.m. Track: Electric & Hybrid Vehicle Components.

- The Expo’s Product Showcase will feature Henkel’s new silicone-free Gap Filler technology. Open to all show delegates, Henkel’s Technical Customer Service Director for Thermal, Dr. Rita Mohanty, will deliver a presentation in Henkel booth 1201 on September 10th at 10:45 a.m.

- Exhibit Theater Presentation -- Why is chemistry essential to EV battery systems?, Bashar Kirma, Henkel Business Development Manager, Exhibit Theater Silver Ballroom, September 10th from 1:00 pm to 1:20 p.m.

- Exhibit Theater Presentation -- The Role of Thermal Adhesives in Heat Dissipation, Anna Javier, Henkel Senior Applications Engineer, Exhibit Theater Silver Ballroom, September 10th from 1:25 p.m. to 1:45 p.m.

- Live battery assembly adhesives and thermal materials presentations in Henkel booth 1201 taking place all three days of the show.

Alongside comprehensive battery materials formulation know-how and application technical expertise, Henkel’s EV battery offer is further underpinned by global R&D test centers and strong partnerships with top automotive manufacturers and research organizations. The Henkel e-Mobility team invites show delegates to learn more about how the company is driving the future of automotive electrification.

* As per current, June 2018 REACH SVHC documentation.